Why lack of support structures is so important in medical 3D printing

We have heard a lot about 3D printing in medicine since its inception, and now, in the time of a global pandemic, the technology has often supported local medics in need. In its history, SLS printing has supported difficult surgeries, whether in the form of tools or visual aids to prepare surgeons for serious operations.

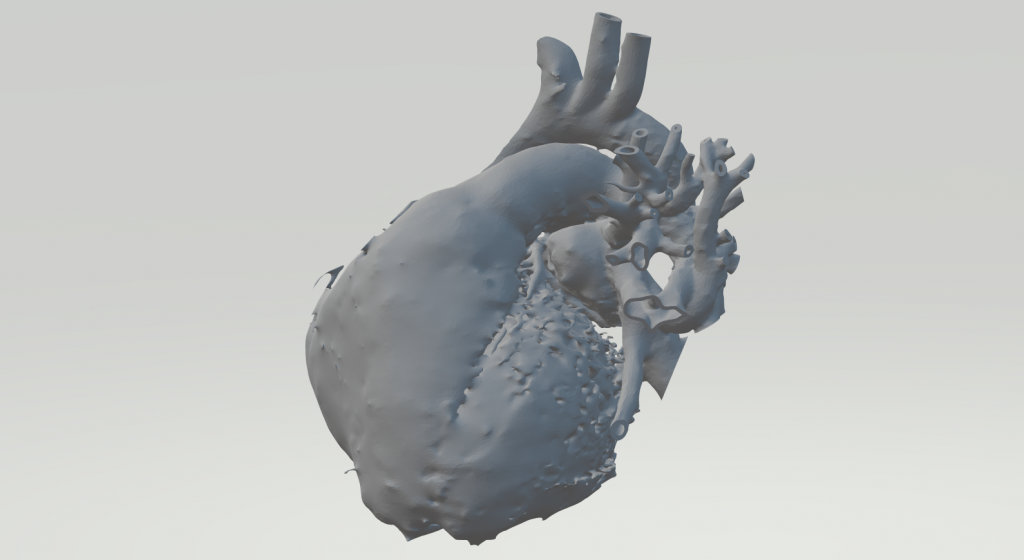

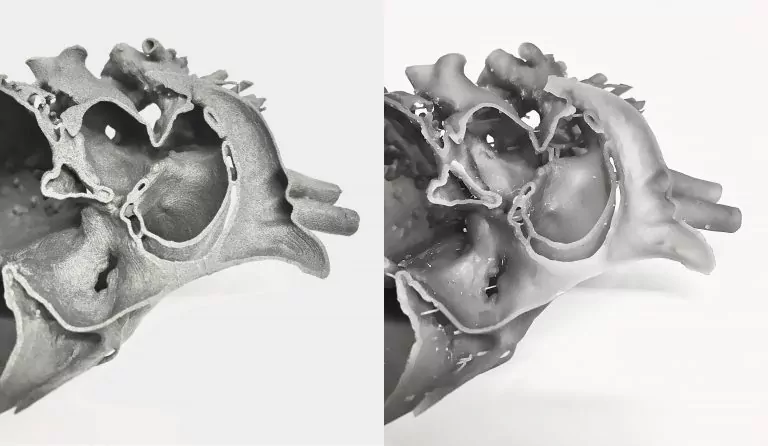

SLS technology has many advantages, it uses materials with properties suitable for many industries. The most important advantage over other methods of 3d printing is the lack of generated additional structures that would have to be removed mechanically or chemically (breaking off / cutting off / dissolving). Thanks to the powder that supports each layer, it is possible to produce the most complex models with various structures and small details. Printouts from the medical industry often belong to this type of element – especially those from tomography or other imaging methods (Fig. 2).

Is any technology suitable for printing medical models?

One of the often mentioned advantages of 3D printing is the ability to print models with the highest geometry complexity, limited only by imagination. Printing technologies, however, differ greatly from each other and their limitations – this is due to the materials and devices used with different designs and the method of layering the material (incrementally – as opposed to subtractive methods). Therefore, each application and geometric model in 3D should be considered individually, analyzed in terms of surface requirements, dimensional tolerance or mechanical properties.

An important factor that should not be forgotten is whether the model requires support structures – where post-processing may harm not only aesthetic but also functional aspects. Many medical applications require complex organic structures with internal features structures. Using the example of heart prints in various technologies, we will present how important it is for such models to omit supporting structures in order to maintain appropriate quality and usability.

Influence of supporting structures on the geometry of prints in SLA, FDM and SLS technologies

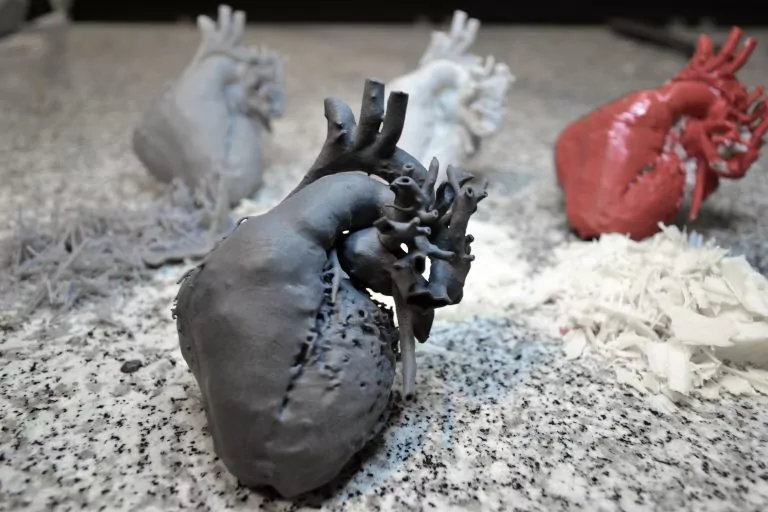

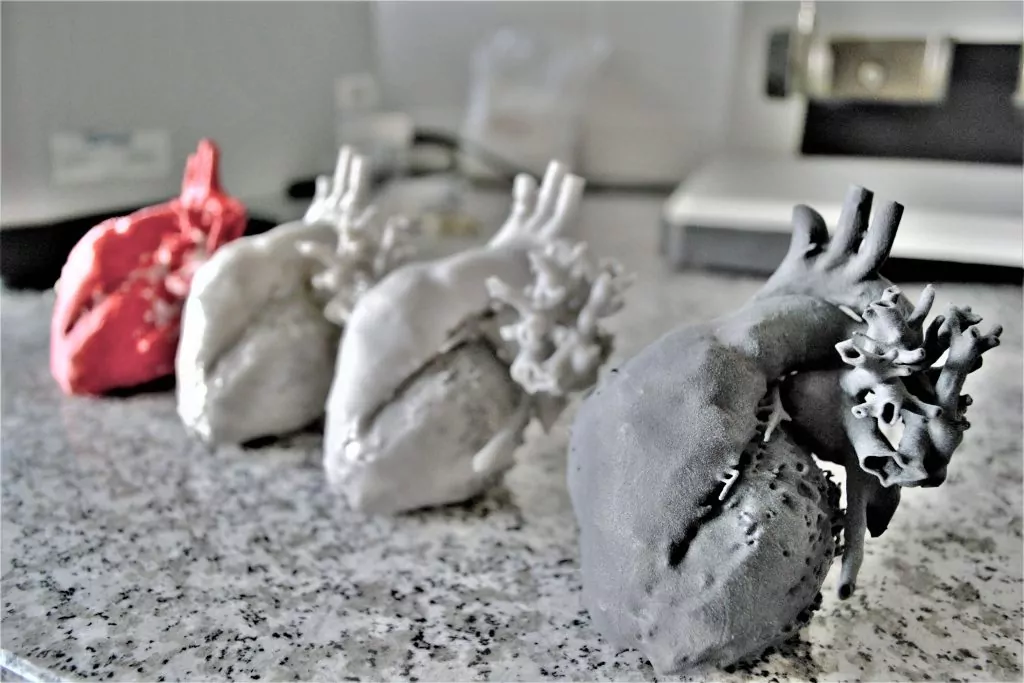

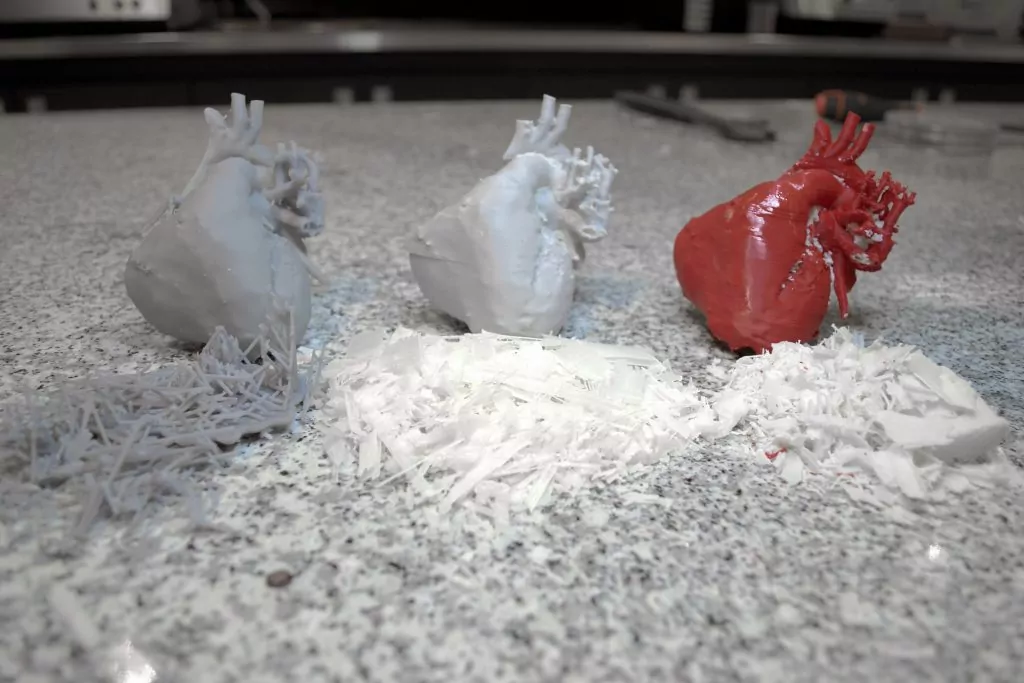

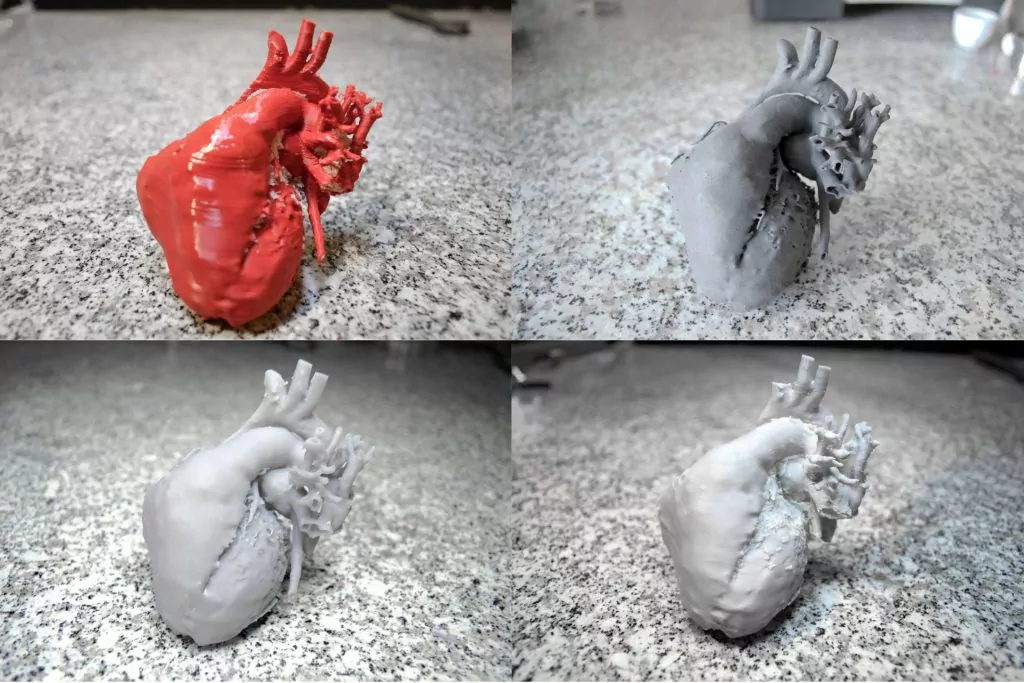

In Fig. 2 you can see the prints (from the left): made of resin (SLA), ABS (FDM), PLA (FDM), and PA12 (SLS). In the case of FDM technology the support structures (most often generated automatically in a slicer) are quite dense and due to the geometry of the model their number is significant. Unfortunately, in this type of geometry, with this technology we will not be able to achieve the desired effect. Even when using soluble support structures – they interfere with the surface, which will leave behind artifacts on the structure. Also, in the case of the heart, some of the elements or sides were not printed properly due to their small dimensions. The layers are clearly visible, they obscure small elements of the model that may be important for medical reasons. Furthermore, the use of post-processing to smooth the surface may cause a loss of detail in the printout.

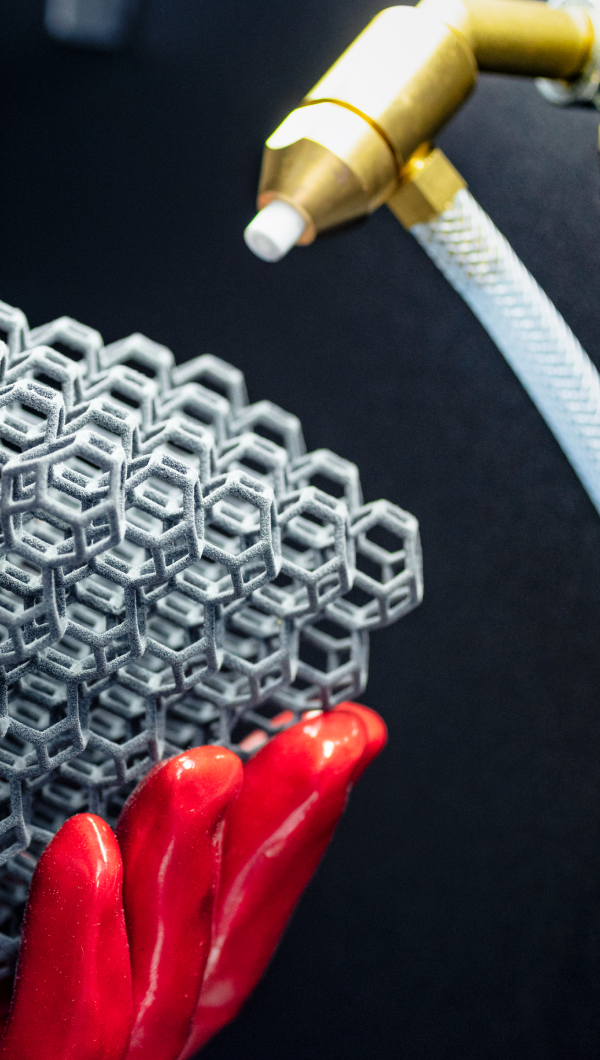

In SLA technology, both the surface and the mapping of elements are much better. Nevertheless, the supporting structures are in some cases so large that it is impossible to remove them without damaging the model (especially with small protruding elements – Fig – close-up on small elements). In addition, removing support structures left artifacts in places that are very difficult to reach with tools that can damage the fragile model. In SLS technology, of course, these additional printed structures do not exist, as the powder that was the support for the model was removed in the sandblaster after printing. This allowed for much more detail and details than in the case of the resin model.

Post-processing

Removing support structures entails additional time spent preparing models. In the case of ABS and PLA models, this can take a long time, especially if the surface of the model is rough and the support does not come off easily. This was the case with the two models of hearts. In some places of the model, the support could be easily removed, while in others it was impossible despite the great force added. In the case of the resin model, the processing was quite simple – the structures in the narrowing between the model surface and the structure had to be cut off. However, in order not to damage such a complex model, it required a lot of time and left artifacts regardless. In the case of the SLS model, fortunately, we have no waste – the leftover powder from the printing process can be refreshed (or in some cases, it does not even have to be) and reused.

Surface

The best surface quality is achieved by SLS and SLA technology, in this case we will exclude FDM technology, which can also create models with excellent surface and low visibility of layers, but not with such complex models. It is not possible to achieve a high quality surface finish over the entire part. SLS and SLA technologies are very similar when it comes to the low visibility of the layers, but in the case of the heart, sharper details and greater surface detail are definitely visible. The resin models appear to be largely smoothed. Many of the tiny details in the resin model have fused to the support structures, leaving only surface artifacts behind.

The internal surfaces achieved by SLS are slightly superior to SLA – no artifacts, no additional structures, no mechanical intervention. In medical applications, for both investigation and surgery preparation, the surface quality of the internal cavities is just as critical as the external features.

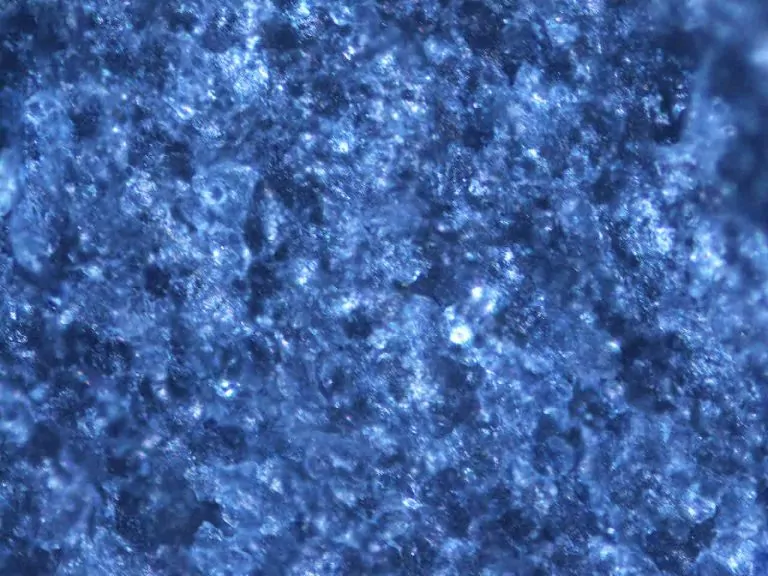

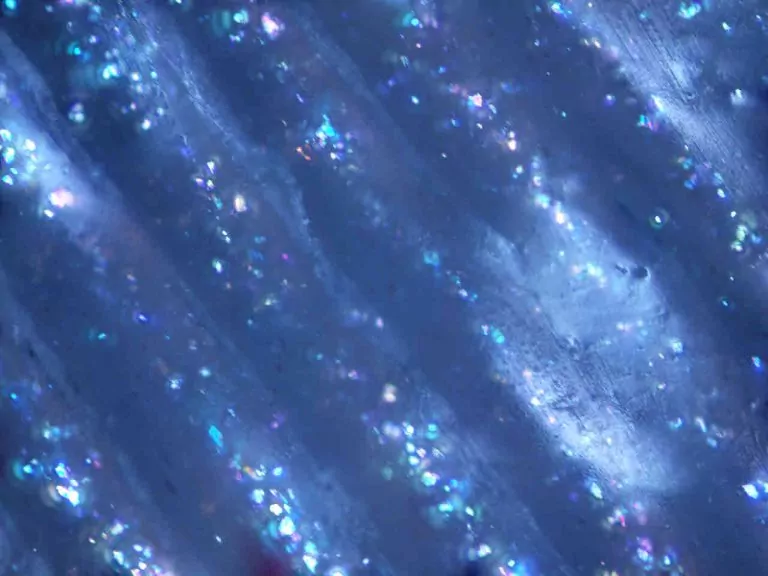

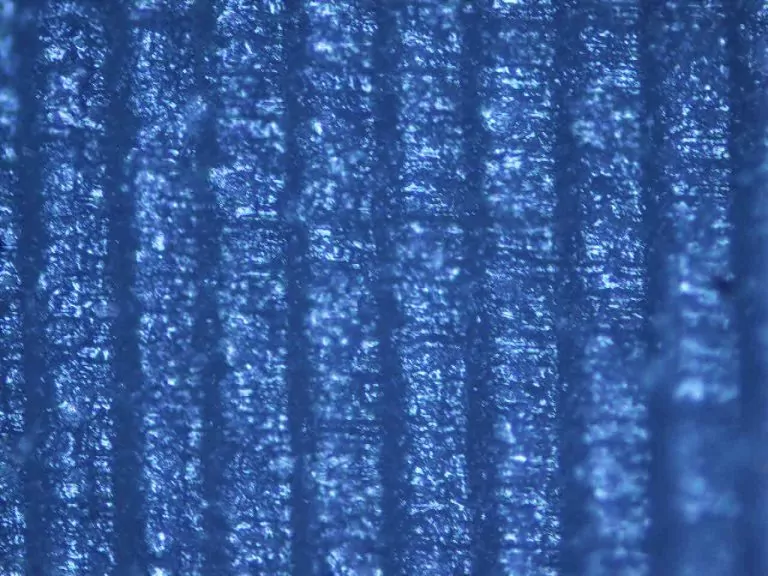

In microscopic view, FDM has large rounded layers visible on the surface – even without a microscope. Resin technologies can use very thin layers – they are also flat which makes them look smooth. In the FDM case, the surface is rough, and the layers are not visible under the microscope – the models, although matte, are smooth and without visible layers to the naked eye.

Accuracy

Due to the presence of remnants from the support structures, some of the geometries could not have the appropriate accuracy. In some of the cavities, there was too much extra material that no measurement is possible even. In the case of such complex models as the example of the heart, many specialized and precise tools are needed to remove such structures.

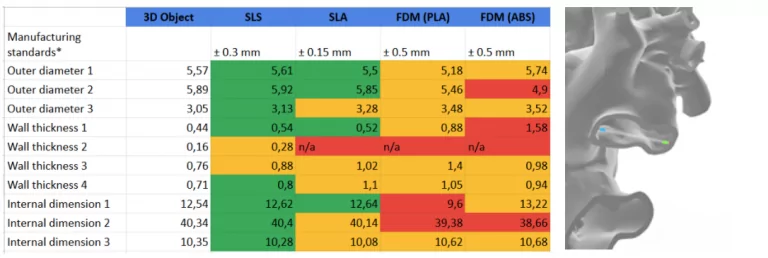

In the case of the resin model, it also turned out that in the depths of the model, the material curing process was not completely finished, which caused the geometry to blur. In the case of accuracy measurements, the SLS technology gains a lot due to the lack of support – the measurements in most cases were within +/- 0.1mm, which can be considered as high accuracy (the manufacturing standard according to 3D Hubs in SLS technology is +/- 0.3mm).

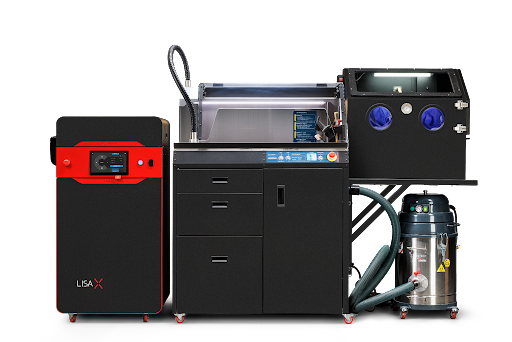

SLS as a perfect solution for medical-organic models

SLS is a technology that enables you to produce geometries that are often impossible to be fully realized with other techniques. The example of the heart shows that medical professionals who work on such complex models will find the part made using SLS the most useful – showing the most details of the geometry. In addition, it leaves no artifacts behind, ensuring its accuracy. Following quick and easy post-processing, it is possible to get a model ready for further analysis immediately after printing. With Sinterit Lisa and the new range of printing peripherals, it is easier to achieve high-quality, high-fidelity parts with complex geometries outside the scope of other printing technologies.