The future for distribution companies based on special Lab

-

showing a design concept expand of the scope of activities

-

prototype new products the possibility of experimenting

-

perform functional explore the feasibility of local vs international supplies

Background

German distribution giant, H. Gautzsch Firmengruppe has two primary businesses – distributing electrical components for industry professionals, and marketing their own home and garden product range, Siena Garden. They have over 1000 employees and are market leaders in both businesses.

Learn more

Why Lisa is a perfect solutiuon for you

Problem

The future of international manufacturing and supply chains is facing some uncertainty driven by the flexibility of AM. Products are no longer only feasible in batches of a thousand parts and production plants can shrink to the size of a kitchen. AM enables companies to return their production to local suppliers and even in-house AM hubs. This next evolution in manufacturing will disrupt the way products are distributed.

Large distributors like Gautzsch will be the first to experience the disruption in manufacturing methods due to additive manufacture on a large scale. Can the innovators at Gautzsch use Additive manufacturing to excel with new capabilities?

Peter Benthues described how their in-house AM Lab is exploring the latest AM trends

Solution

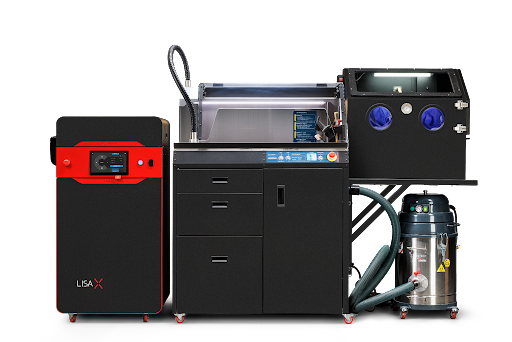

A.A.G. Stucchi looked for a solution that would avoid the construction of molds until the final version of the new project. After getting acquainted with the offer, they decided to purchase the SLS Sinterit Lisa PRO 3D printer. Gautzsch launched an in-house AM lab to investigate the potential of AM and how it may influence the future of distribution.They decided to add an SLS printer from Sinterit to broaden the scope of their investigation into more advanced polymers.

“The LISA is one of the few economically feasible solutions in the first stages of any AM Strategy. At lower volumes, it is a perfect solution.”

Adding the Sinterit Lisa didn’t require any extra ventilation and occupies less floor space than a typical office scanner/printer. With the addition of the Sinterit Lisa to their AM Lab, Gautzsch is able to experiment with a variety of parts currently in their offer. They can explore the feasibility of local vs. international supplies, and gain an insight into the products that will likely move to AM in the near future. This knowledge is invaluable when designing the distribution networks of the future.

“For a company at the beginning of an investigation, support from, and discussion with the technology experts is extremely beneficial.”

Open SLS platform is a key to success.

Visit our customer’s website:

-

showing a design concept expand of the scope of activities

-

prototype new products the possibility of experimenting

-

perform functional explore the feasibility of local vs international supplies